Why in the News?

IIT Madras-incubated space startup Agnikul Cosmos has successfully launched world's first single-piece 3D printed rocket engine of Rocket Agnibaan SOrTeD.

More about the News

- Also, recently, Indian Space Research Organisation (ISRO) successfully conducted hot testing of liquid rocket engine which is manufactured through Additive manufacturing (AM) or 3D Printing Technology.

- The engine used is the PS4 (fourth stage) engine of Polar Satellite Launch Vehicle (PSLV).

- It is developed by the Liquid Propulsion Systems Centre (LPSC), ISRO.

- Laser Powder Bed Fusion (LPBF) technique has been employed in it.

About Agnibaan SOrTeD

- Rocket Agnibaan SOrTeD (SubOrbital Technological Demonstrator) is India's first semi-cryogenic engine-powered rocket launch flight.

- A suborbital flight is a flight up to a very high altitude which does not involve sending the vehicle into orbit.

- Its engine has been developed with the help of AM or 3D Printing technology.

- Launched from: India's first privately developed launchpad called 'Dhanush' established by Agnikul at Sriharikota in Andhra Pradesh.

- Launch was supported by the ISRO and the Indian National Space Promotion and Authorisation Centre (IN-SPACe).

- Stages and Carrying Capacity: Two-stage rocket with a capacity to carry payloads upto 100 kg to a height of 700 km (in a Low Earth Orbit (LEO). Also, there is optional 3rd stage of Agnibaan which is known as baby stage.

- It can access both low- and high-inclination orbits.

- It takes about 75 hours to build one rocket engine, which is much faster than the standard 10 to 12 weeks required to build a similar-sized rocket engine using conventional processes.

About Semi-Cryogenic Engine (SCE)

|

About AM / 3D Printing

- It is the technology that constructs a three-dimensional object from a digital 3D model by adding material layer by layer.

- It is the opposite of subtractive (traditional) manufacturing, in which an object is created by cutting away at a solid block of material.

- AM materials include thermoplastics, metal and metal alloys, ceramics and biomaterials such as bioinks.

Process involved in AM / 3D Printing

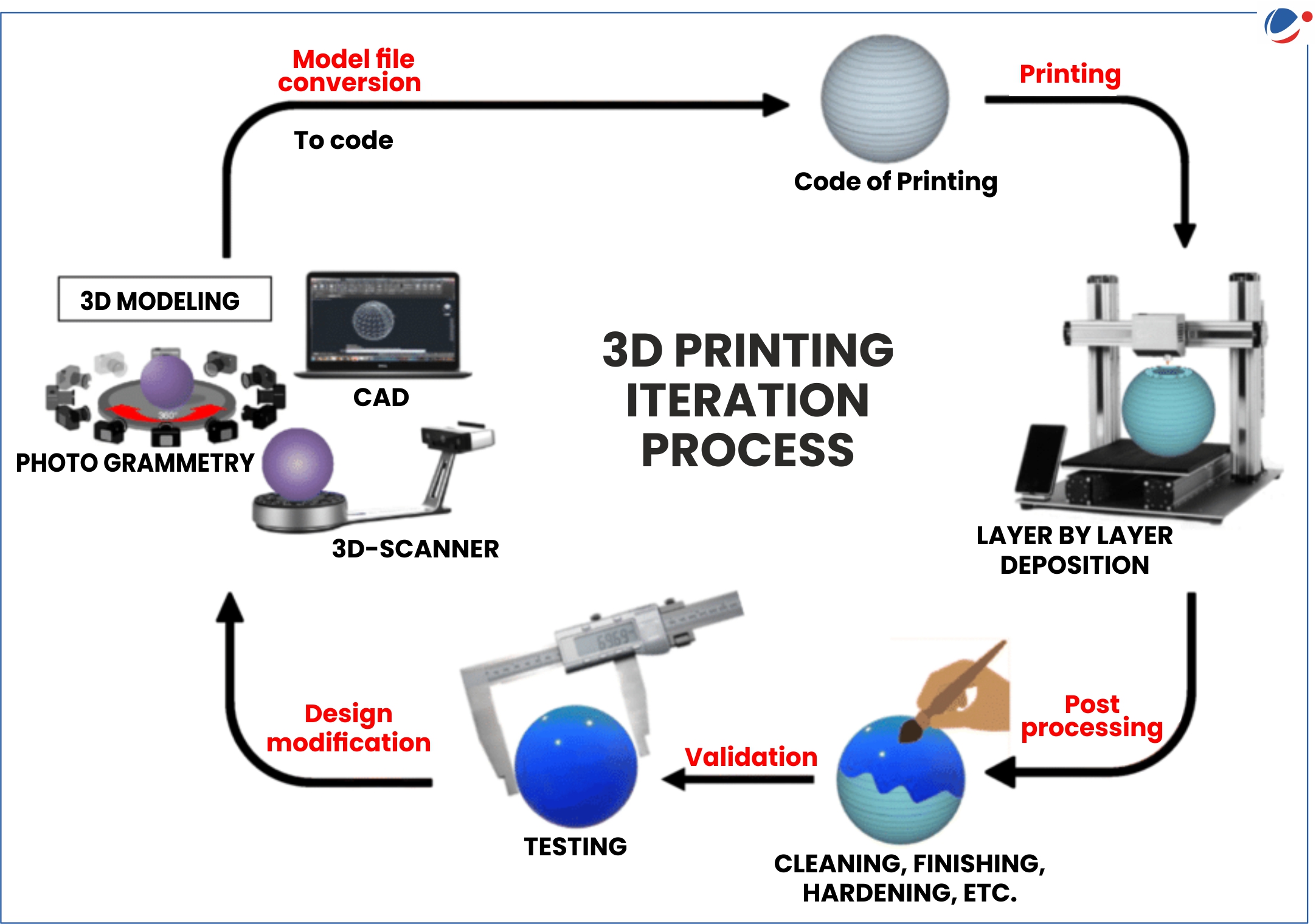

- Additive Manufacturing technologies are essentially classified into virtual and physical models.

- The virtual model represents computational models and applications for simulation and optimization.

- 3D model is prepared of the required object on computer-aid design (CAD) software.

- The physical model represents three-dimensional virtual design models that are then speedily fabricated into a physical object. This process is known as rapid prototyping.

- Then, 3D printers are used for the creation of structure.

- 3D printers are physical machines that translate digital design files into actual objects or parts.

- It involved different methods such as- Material Jetting, Directed Energy Deposition, Sheet Lamination etc.

Key Applications | |

| Aerospace & Defence: Landing gears, Thrust reverser doors, Small surveillance drones, high-value components etc. | Automotive: Engine components, gear boxes, air inlet, etc. |

| Electronics: Wearable devices, soft robots, Data processing technologies, RFID (Radio Frequency Identification) devices, etc. | Healthcare: Surgical Models (Organs), Surgical Instruments (medical) etc. |

| Consumer Goods: Jewellery, shoes, clothing, cosmetics products, toys, figurines, furniture, office accessories, musical instruments, bicycles, and food products (E.g. confectionery items). | |

Advantages of 3D Printing

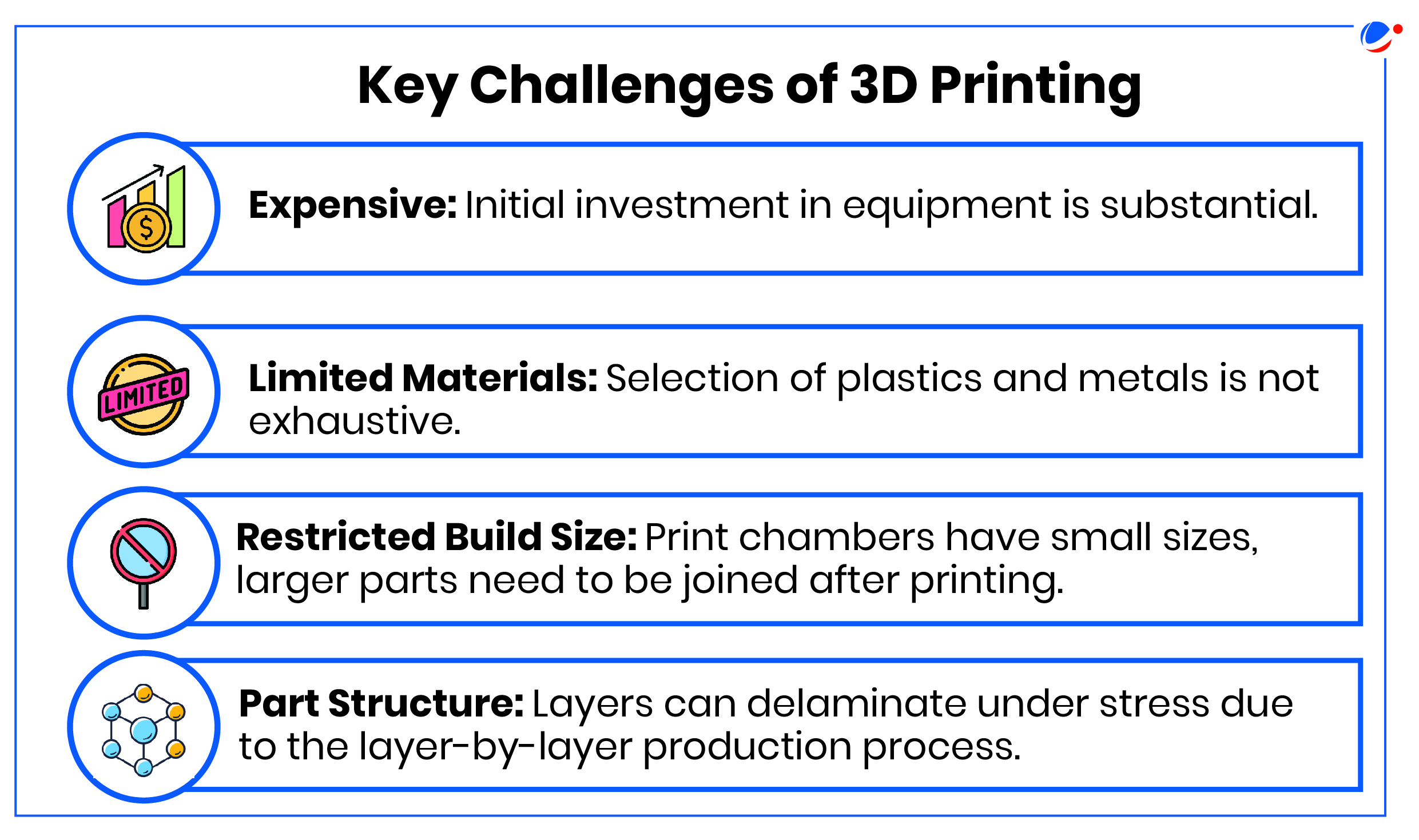

- Rapid Prototyping: 3D Printing has considerably expedited prototyping, serving as a catalyst in the product development cycle. It will facilitate swift transition of ideas from concept to tangible form.

- Design Flexibility: Intricate designs, which would have been nearly impossible or prohibitively expensive with conventional manufacturing methods, are now feasible.

- For instance, aerospace and automotive industries can create components with complex structure without compromising strength.

- Sustainability: It significantly reduces material waste by only consuming what's necessary for the print and the support structures.

- Also it uses sustainable materials. E.g. Polylactic Acid (PLA) is a popular 3D printing material derived from renewable resources like corn starch or sugarcane.

- On-demand Production: Companies can move from mass production to mass customization, allowing for the swift manufacturing of parts based on specific demand.

- Quality Assurance: With digital design validation, potential errors in the design process are identified and corrected even before the printing begins.

- The layer-by-layer technique of 3D printers ensures consistency across the board.

- Supply Chain Enhancement: Eliminates the dependence on large warehouses to store bulk items and components.

Key Initiatives Taken to Promote 3D Printing

Recent Developments in India

|

Conclusion

3D Printing has revolutionised the manufacturing process. In India, it is in a nascent stage. Implementation of National Strategy for Additive Manufacturing in letter and spirit will decide its future. Private sector needs to shift towards it as it has multiple benefits over traditional methods.