Why in the News?

Union Minister for Petroleum and Natural Gas announced India's achievement of 20% Ethanol blending target in petrol.

More on the News

- The target was achieved as envisaged in Ethanol Blended Petrol (EBP) Programme.

- Ethanol blending in petrol increased from 1.5% in 2014 to 20% in 2025 (Nearly 13-fold increase).

About Ethanol

|

About Ethanol Blended Petrol (EBP) Programme

- Genesis: Launched in 2003 to promote blending of ethanol in petrol.

- About Ethanol Blending

- Definition: Ethanol blending refers to the process of mixing ethanol with petrol to create a more sustainable and cleaner burning fuel.

- Types: E10 (10% Ethanol by Volume), E20 (20% Ethanol), E85 fuel (85% ethanol by volume).

- The use of E-20 gives better acceleration, better ride quality and lowered carbon emissions by approximately 30% as compared to E10 fuel.

- Target: National Policy on Biofuels (2018), as amended in 2022, advanced the target of 20% blending of ethanol in petrol to 2025-26 from 2030.

- National Policy on Biofuels:

- Use of Sugarcane Juice, Sugar Beet, Cassava, Damaged food grains, Rotten Potatoes, unfit for human consumption for ethanol production.

- Use of Surplus food grains to be used for ethanol production and blending with petrol.

- Achievement: Ethanol production increased from 38 crore liters in 2014 to over 660 crore liters in 2025.

- National Policy on Biofuels:

Challenges of Ethanol Blending in India

- Food Security and Inflation: Biofuel expansion could exacerbate food insecurity, particularly for vulnerable populations as per FAO Report 2023. E.g. Over diversion of food crops for ethanol production.

- Environment: Ethanol blending is heavily dependent on Sugarcane in India, a water intensive crop affecting water aquifers.

- Technological and Vehicle Cost: India's vehicle fleet transitioning to E20 and beyond requires modifications in engine design and fuel systems, which may be costly.

- Many older vehicles and two-wheelers lack ethanol-compatible parts, making them less tolerant to higher blends.

- Fuel efficiency and Vehicle Integrity: Ethanol, being lower in energy density than petrol, results in a marginal decrease in mileage.

- Older engines may struggle with air-fuel adjustments on ethanol blends, resulting in drivability and emissions problems.

- Ethanol is prone to water absorption and phase separation, increasing the risk of clogging and fuel system failures.

- Supply of Ethanol:

- Availability of ethanol across the country: E.g. Ethanol blending has not been taken up in North-East states due to non-availability of feedstock or industries or high cost of logistics.

- Restrictions on inter-state movement of ethanol due to non-implementation of the amended provisions of Industries (Development & Regulation) Act, 1951 by all the States.

- The high cost of logistics and transport related emissions due to Transport of ethanol to different places.

- The need for storage infrastructure for ethanol at marketing terminals / depots.

Initiatives facilitating Ethanol Blending

- PM JIVAN (Jaiv Indhan- Vatavaran Anukool fasal Awashesh Nivaran) Yojana: For providing financial support to integrated bio-ethanol projects for setting up Second Generation (2G) ethanol projects

- Ethanol Interest Subvention Schemes (EISS) launched to foster the establishment of Dedicated Ethanol Plants (DEPs).

- Reduction in GST on ethanol meant for EBP Programme from 18% to 5%. However, crude ethanol still continues to be taxed at 18%.

- Amendment to Industries (Development & Regulation) Act, 1951 for smooth movement of ethanol across country.

Conclusion

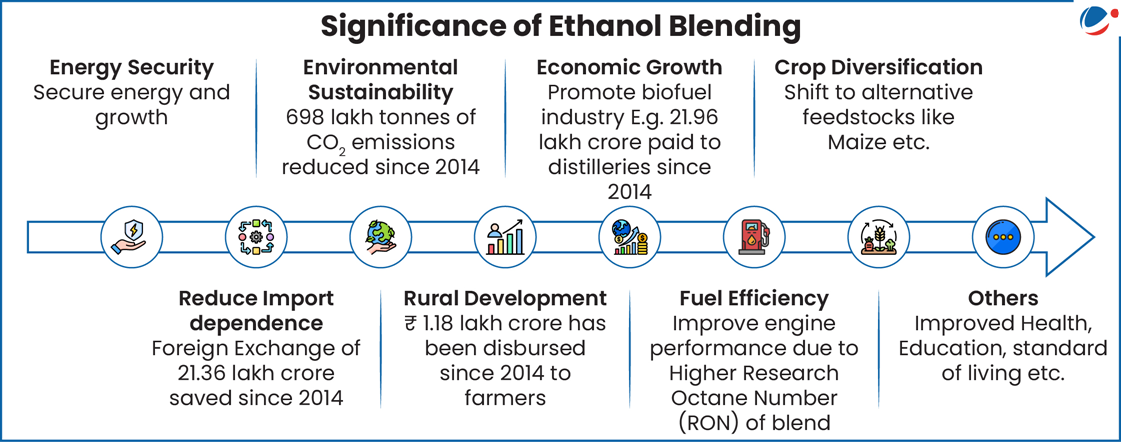

India's commitment to ethanol blending represents a transformative approach to energy security, environmental sustainability, and economic development. With potential biodiesel in pipeline, care must be taken to cater to the challenges encountered in the ethanol-blended petrol introduction. A phased roll-out is thus the need of the hour.